Infection control is a priority for hospital management, from unit managers to the CEO. The Centers for Disease Control and Prevention reports that 1 out of every 31 hospitalized patients is diagnosed with a healthcare-associated infection (HAI).

Surfaces, such as cabinets, work areas, and carts, can contribute to the spread of disease-causing organisms. Horizontal and vertical surfaces, especially high-touch areas, can collect splatters, dust, and microorganisms from staff and patients.

Pathogens land on these surfaces and are picked up by hands, clothing, and medical supplies and transmitted to other patients as staff and equipment move from room to room.

One of the first considerations when choosing healthcare surfaces is to evaluate the materials used and their construction.

The International Health Facility Guidelines (iHFG) state that facilities should choose materials and surfaces for patient care areas that are:

- not prone to collecting dust or moisture,

- easy to clean,

- sealed or seamless,

- impermeable, and

- smooth.

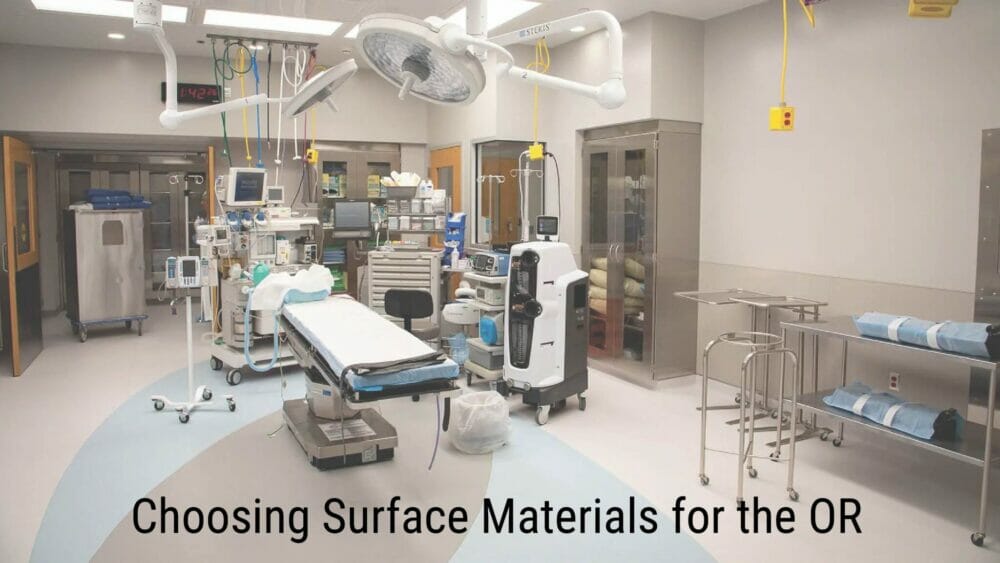

As high-risk areas, operating rooms benefit from surface materials that have stood the test of time and meet the above criteria.

The Best Surface Material for Use in the Operating Room

Stainless steel was first produced 110 years ago. Harry Brearley of the U.K. found that when he mixed iron with chromium, the material produced would not rust. Shortly after his discovery, surgical instruments made of stainless steel began appearing in operating theaters.

Today, stainless steel is still the best surface material available for use in operating rooms. Read on for a list of reasons that stainless steel has been and continues to be the number one choice for high-risk, high-touch healthcare surfaces.

Stainless steel resists rust and corrosion

When stainless steel contains at least 10.5% chromium, the chromium oxidizes, and a film forms on the surface. This passive film is nonporous and resists corrosion and rust. If stainless steel is scratched, the exposed chromium will oxidize and fill in those areas with more film. This self-healing property is a primary reason that stainless steel is the material of choice for medical environments.

Stainless steel is easy to clean

Stainless steel, regardless of whether it is new or previously used and cleaned multiple times, can be adequately disinfected.

In 2017, Manchester Metropolitan University and AgroParis Tech were asked by Team Stainless to study whether older stainless steel could be disinfected to the same degree as new stainless steel. Researchers found that after being contaminated with Staphylococcus aureus and Pseudomonas aeruginosa, the disinfection effectiveness rates were the same across all samples.

Stainless steel can withstand sterilization

Hospital-grade stainless steel holds up to the most rigorous cleaning agents and techniques, including heat sterilization and disinfecting agents, no matter the age or condition of the steel.

Stainless steel is stable

Stainless steel used in hospitals has an alloy content ratio that contributes to its stability and makes it an inert material. This means that the passive film produced by the oxidation of chromium prevents the components of stainless steel from migrating into the surrounding environment.

Stainless steel is non-magnetic

Magnetic resonance imaging (MRI), dental devices, implantable devices, and the delivery of cancer treatments are some ways that magnets are used in healthcare. Surfaces used in these environments must be non-magnetic.

Stainless steel is moldable

Stainless steel can be formed into almost any shape. This property makes stainless steel ideal for constructing the many items used in high-risk hospital units, such as surgical tools, trays, tables, beds, cart surfaces, walls, and cabinets.

Stainless steel is strong

Stainless steel will withstand a fast-paced hospital environment, resisting breakage from drops or surgical instruments tossed into a stainless steel pan.

Stainless steel is recyclable

Stainless steel, if cared for properly, can last for decades or even longer. But when it’s time to replace those kidney pans, they can get a new life, maybe as a sink.

While stainless steel is preferred for high-risk patient care environments, it may not always be appropriate for or needed in other areas.

High-Tech Materials That Inhibit or Kill Pathogens

The Center for Health Design recommends that hospitals choose surfaces that help reduce the number of microorganisms that can collect or survive on them. Newer technology has produced surface materials that help limit the number of pathogens that stick to a surface or actively kill pathogens.

For example, materials that incorporate copper or silver may reduce bioburden.

Other surfaces have a texture that resists the adherence of microbes.

InnerSpace offers a cabinet material, AireCore, that meets the International Health Facility Guidelines but at a lower cost than stainless steel.

Some surface materials incorporate antimicrobial compounds. High-touch products, such as InnerSpace’s Pace procedure carts, are often manufactured with Antimicrobial ABS thermoplastic polymers.

Selecting surface materials that help reduce the number of pathogens in high-risk areas helps protect both patients and staff. InnerSpace offers an array of customizable options that can help your organization meet your infection control goals.

Cindy Blye

Content WriterCindy Blye, BSN, RN, CCM is a Registered Nurse and Certified Case Manager. She is an Alumni of West Virginia University School of Nursing (BSN), and a member of the Association of Health Care Journalists and The Authors Guild.